How COVID-19 Will Affect Warehouse Technologies in 2021 and Beyond

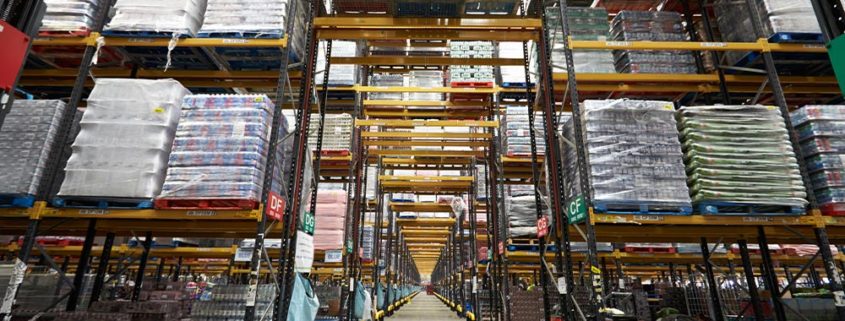

COVID-19 saw a dramatic change in the way that people interact and shop across the globe. Few sectors felt the wake of COVID-19 as hard as the warehousing and restaurant sectors. But while restaurants saw their demands dramatically decrease, many warehouses could scarcely keep up with demand. 2021 and the post-COVID world is going to see warehouse technologies changing.

In General, Warehouses Will Be Doing More With Less

Warehouses are going to continue seeing increased activity as people continue to make purchases online. Many people simply got used to having everything delivered to them during COVID and they aren’t going to go back to the shops. Brick-and-mortar retailers are likely to see decreased sales while online stores and eCommerce will see increased sales. But to keep their profit margins and logistics tight, warehouses are going to be meeting a lot of this demand through automation and process improvement, rather than increased hiring.

Many Industries Will Turn Toward Warehousing in Light of eCommerce

Grocery stores, as an example, are starting to move toward cold warehousing services rather than brick-and-mortar stores that can be browsed. Stores that have traditionally operated as a showroom, such as appliance stores or even mattress stores, may find themselves turning into warehouses and focusing on their eCommerce presence. This will again increase the need for warehouses and reliable warehouse technology.

Companies Will Be Providing Workers With AR Capabilities

While many warehouses are going to automate, they will likely still rely upon workers for key processes. These workers are very likely to be using heads-up displays, augmented reality, sensors, and other always-present IoT technologies. AR can lead pickers directly to items, keep a running tally of the items already picked, and track core metrics about user performance. Augmented reality can help individuals not only complete their jobs faster but avoid error. AR was already moving toward this direction, but the need for faster, more accurate operations during COVID-19 will likely fuel adoption.

Machine Learning and Simulations Will Be Used to Improve Operations

Logistics becomes a real problem when warehouses start to do so much more. Warehouses and logistics and shipping companies in general are going to be increasingly using machine learning and simulations to improve upon their processes and operations. Warehouses can create complete clones of themselves inside of a virtual space to simulate how different inventorying, picking, and shipping operations could work, thereby identifying the methods that are most effective without having to test the solutions out in real-time.

While the pandemic may eventually wane, the consequences of it may amplify. COVID served as an accelerant, forcing many changes to occur faster than they otherwise would — but these were changes that were already in the works.